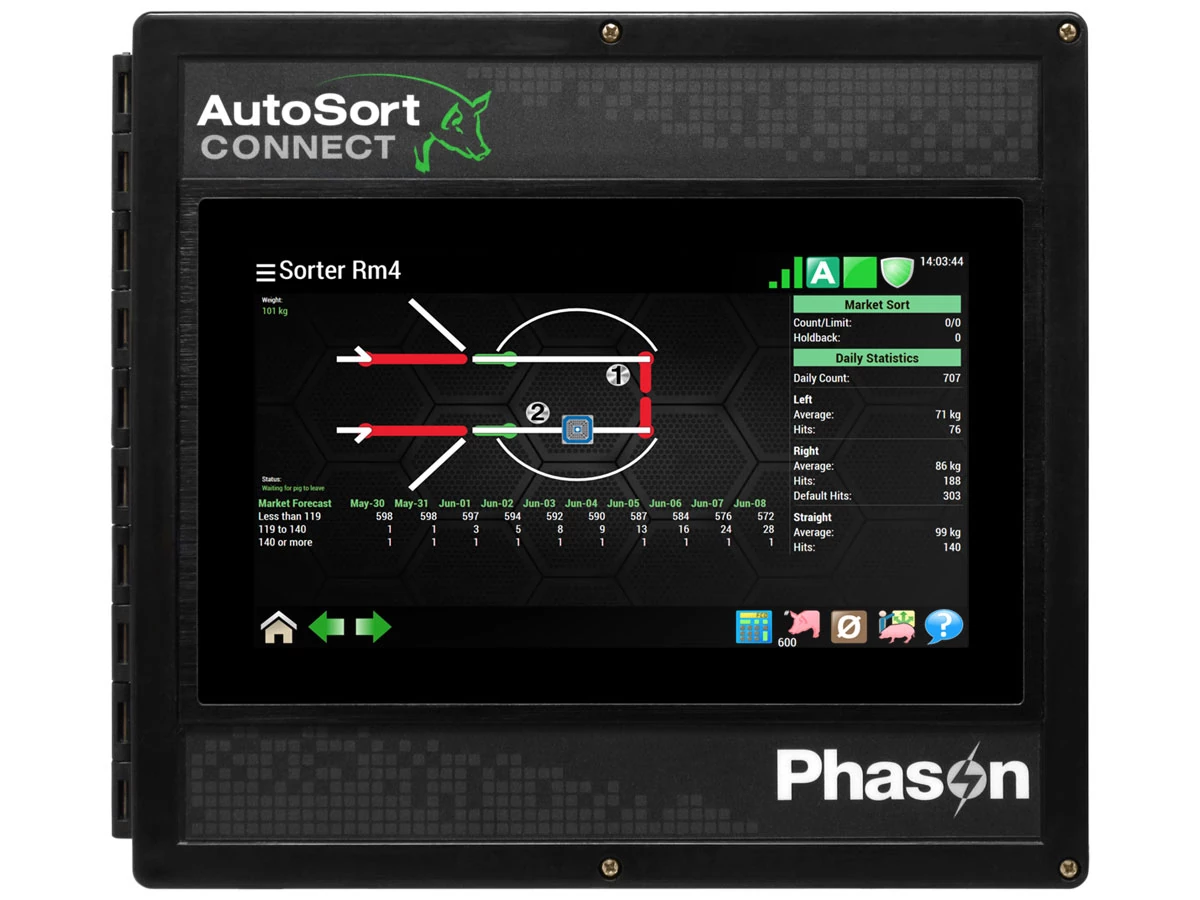

Barn operations require constant monitoring and adjustments—from feed distribution to air circulation and lighting. Instead of managing each system separately, AutoFlex Connect integrates them all, creating a smart, responsive environment that maximizes efficiency and reduces operational costs.

Why Full System Automation Matters

Managing multiple systems manually leads to inconsistencies, inefficiencies, and labor-intensive processes. With AutoFlex Connect:

- Feeding, ventilation, and climate control work together to create optimal conditions.

- Automated scheduling ensures feeding, lighting, and ventilation adjust based on time of day, temperature, or occupancy.

- Producers can monitor everything remotely, making adjustments as needed in real-time.

How AutoFlex Connect Integrates with Barn Systems

Chain Disk Feed System and Feed Loop

- Optimized feed scheduling for better herd nutrition

- Blockage detection to prevent disruptions in feed delivery

- Motor load balancing to reduce wear and maintenance

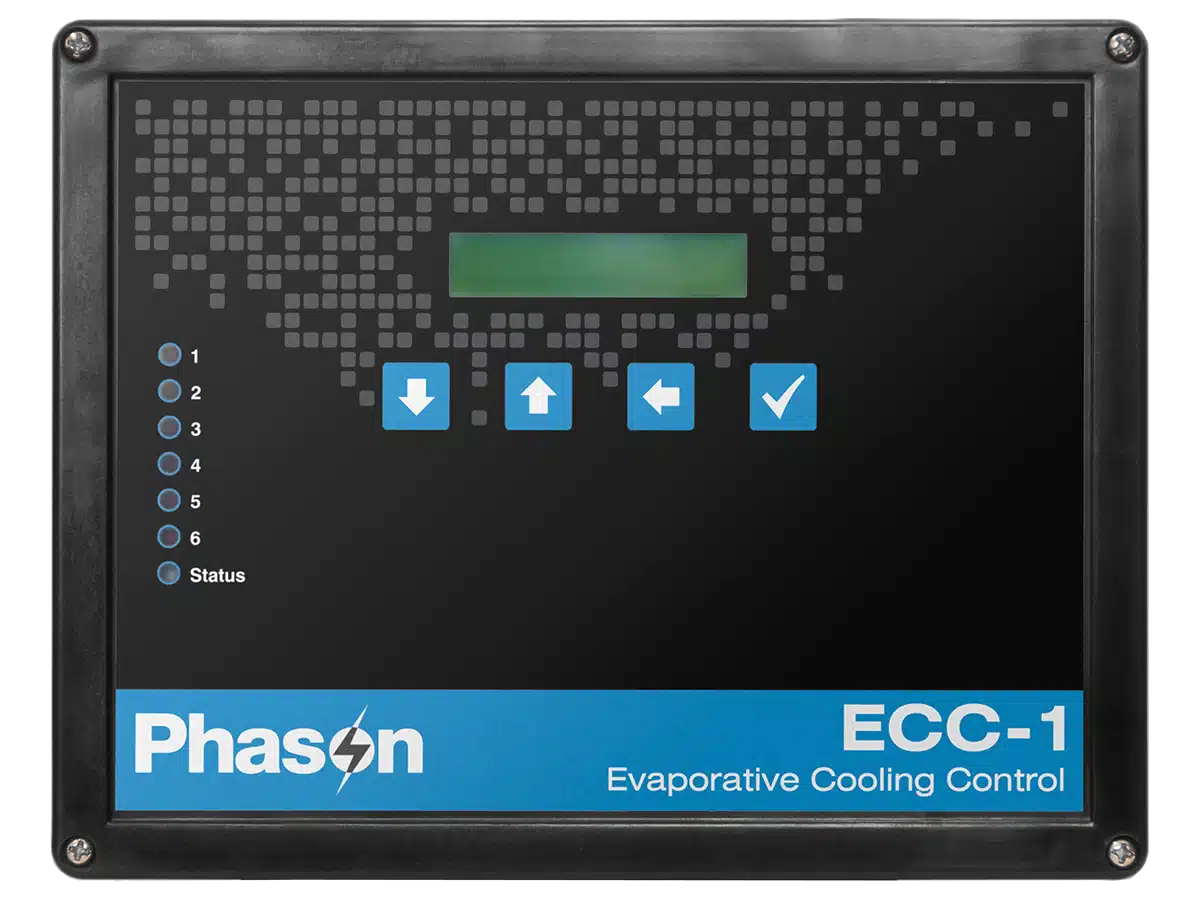

Ventilation and Airflow Management

- Fan speed automation based on humidity, temperature, and air quality

- CO2 and ammonia monitoring to prevents air quality issues

- Climate control synchronization ensures stable barn climate

Lighting and Day-Night Cycle Management

- Synchronizes with feeding schedules to support optimal growth

- Reduces energy use by dimming or turning off lights in unoccupied areas

- Automates transitions between day and night cycles, reducing stress on animals

Remote Access & Alerts

- Monitor feed systems, ventilation, and lighting from anywhere

- Receive instant notifications for maintenance needs, motor failures, or feed flow issues

- Adjust settings remotely, saving time and increasing efficiency

Why Barn Operators Benefit from AutoFlex Connect

- Improved operational efficiency—Automation reduces human error and ensures precision.

- Cost savings—Synchronizing feed, airflow, and lighting lowers energy and feed waste costs.

- Better animal growth—Pigs get precisely-scheduled feed.

- Less downtime—Preventative alerts mean maintenance can be handled before failures occur.

With one system managing everything, barn operators spend less time adjusting settings and more time focusing on production.