What is a ventilation system?

Ventilation systems are intended to provide optimum living conditions for pigs. A well-managed, functioning, and efficient ventilation system draws fresh air into a building and removes stale air containing microbes, dust, harmful gases, and water vapor. Inefficient ventilation is harmful to pig and staff performance, particularly on hot days, and costs more to run.

The optimum environment should enhance voluntary feed intake and minimize heat and other environmental stresses that affect pig and worker health.

The purpose of a ventilation system is to bring fresh, outside air into a building through planned openings and thoroughly mix it with the stale inside air. Good ventilation will exhaust heat, moisture, and air contaminants from the building, while lowering temperature, humidity, and contamination levels.

Types of ventilation

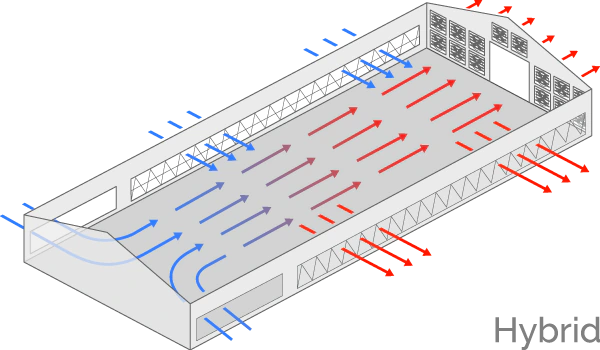

The ventilation system is a key component to the barn design. The three most common systems are all-mechanical, mechanical/natural, and all-natural.

Mechanical ventilation

There are two categories of mechanical ventilation:

- A traditional system with air inlets in the ceiling and fans in the sidewall and pits;

- A three-season (fall, winter, and spring) system with traditional during the three seasons, but, adding tunnel ventilation during hot weather.

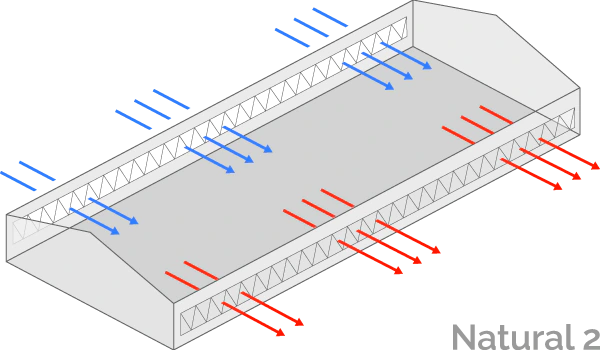

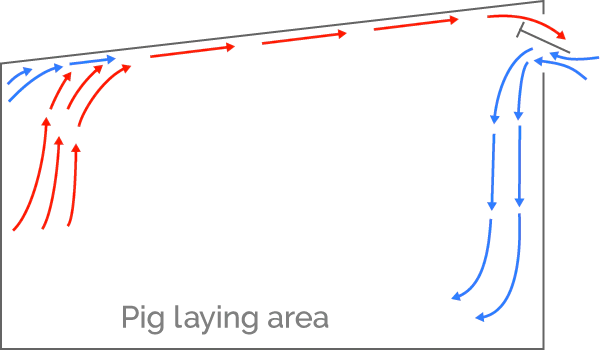

Natural ventilation

In natural ventilation, the barn is equipped with curtains in the sidewalls that are powered by motors called curtain machines or winches. These barns are sometimes referred to as “curtain-sided barns”. Natural mode is generally used during mild or moderate weather.

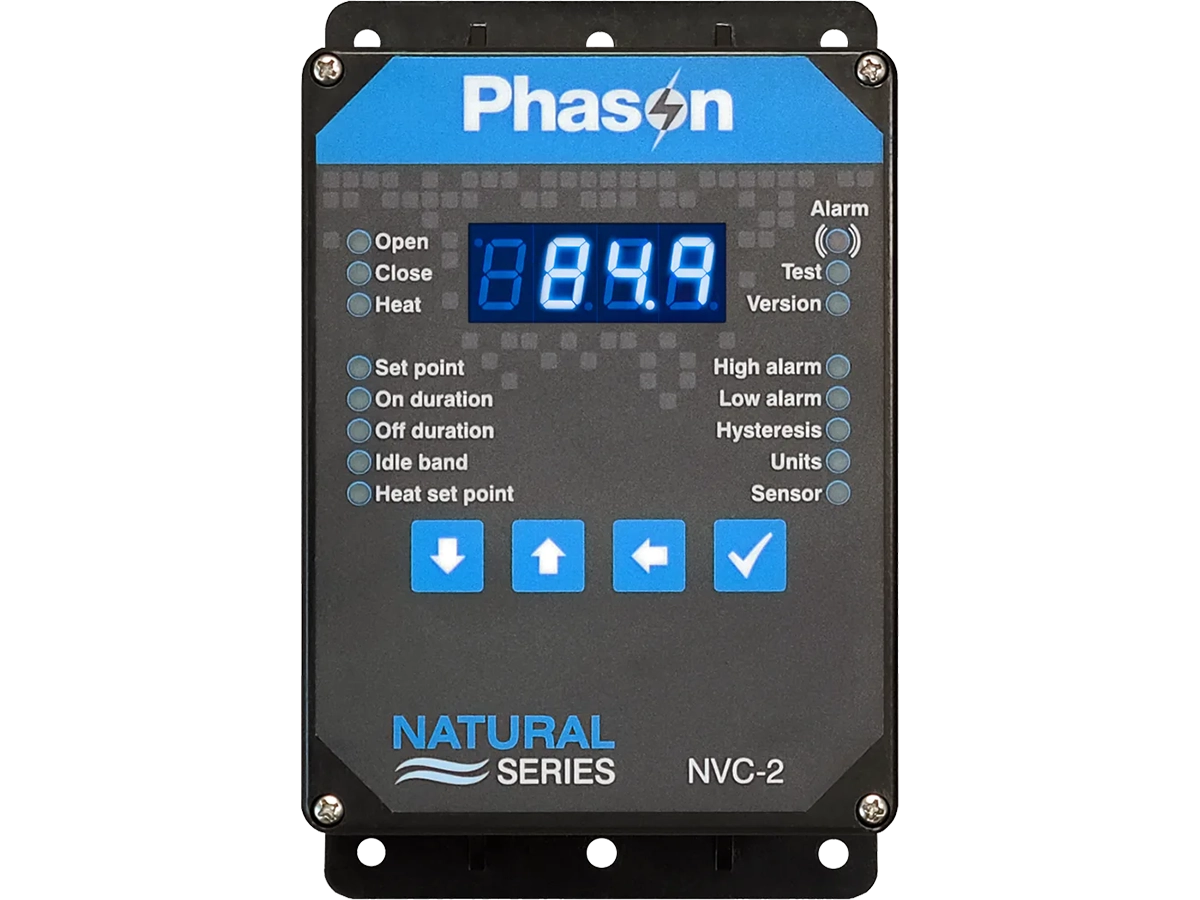

Curtain control uses an idle band. An idle band is a desired temperature range. When the temperature is within the idle band, the control maintains the curtain position. When the temperature rises above or drops below the idle band, the control adjusts the position of the curtains to allow more or less air into the building.

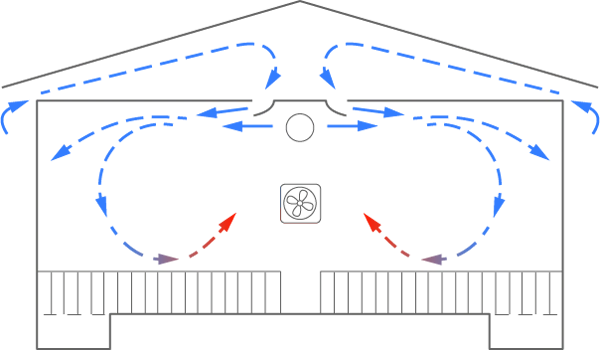

Power mode

In power mode, the barn uses fans and air inlets to exhaust heat and stale air from the building and bring fresh air in. The fans and inlets are on opposite sides of the barn.

The control adjusts the speed of the fans and position of the air inlets depending on the temperature inside the barn. As the temperature rises above the set point, fan speed increases and the inlets open more. When the temperature falls below the set point, fan speed decreases and the inlets close more.

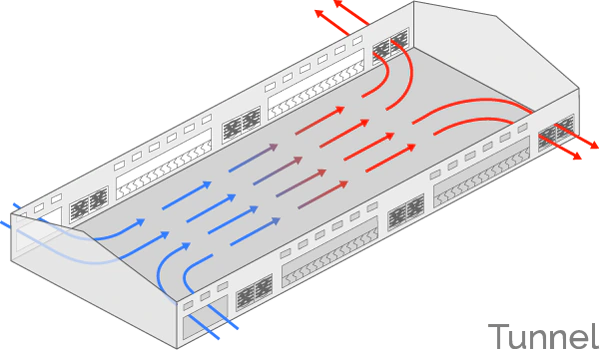

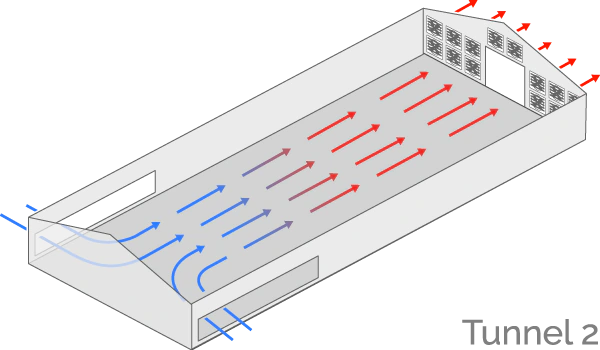

Tunnel mode

Natural and standard power-ventilated barns switch to tunnel mode when the other modes cannot sufficiently cool the barn.

In tunnel mode, one end of the barn has a group of large fans, while the other end has a large inlet area. As the temperature increases, the inlet opens and fan speed increases. The breeze created by tunnel mode, usually 5 or 6 mph, produces a wind chill effect that cools the animals.