Innovative Ventilation and Electronic Control Solutions

We develop and manufacture best-in-class ventilation and electronic control systems to manage and control your facility with confidence.

Our Solutions

Explore our solutions for your farm, shop, or greenhouse.

What We Do

Phason Controls is an AgTech company that specializes in the development and manufacturing of innovative electronic controls and systems for the livestock and agricultural sectors. We are committed to delivering high-quality products that are built to withstand the harsh conditions of agricultural environments. We've been doing it since 1985.

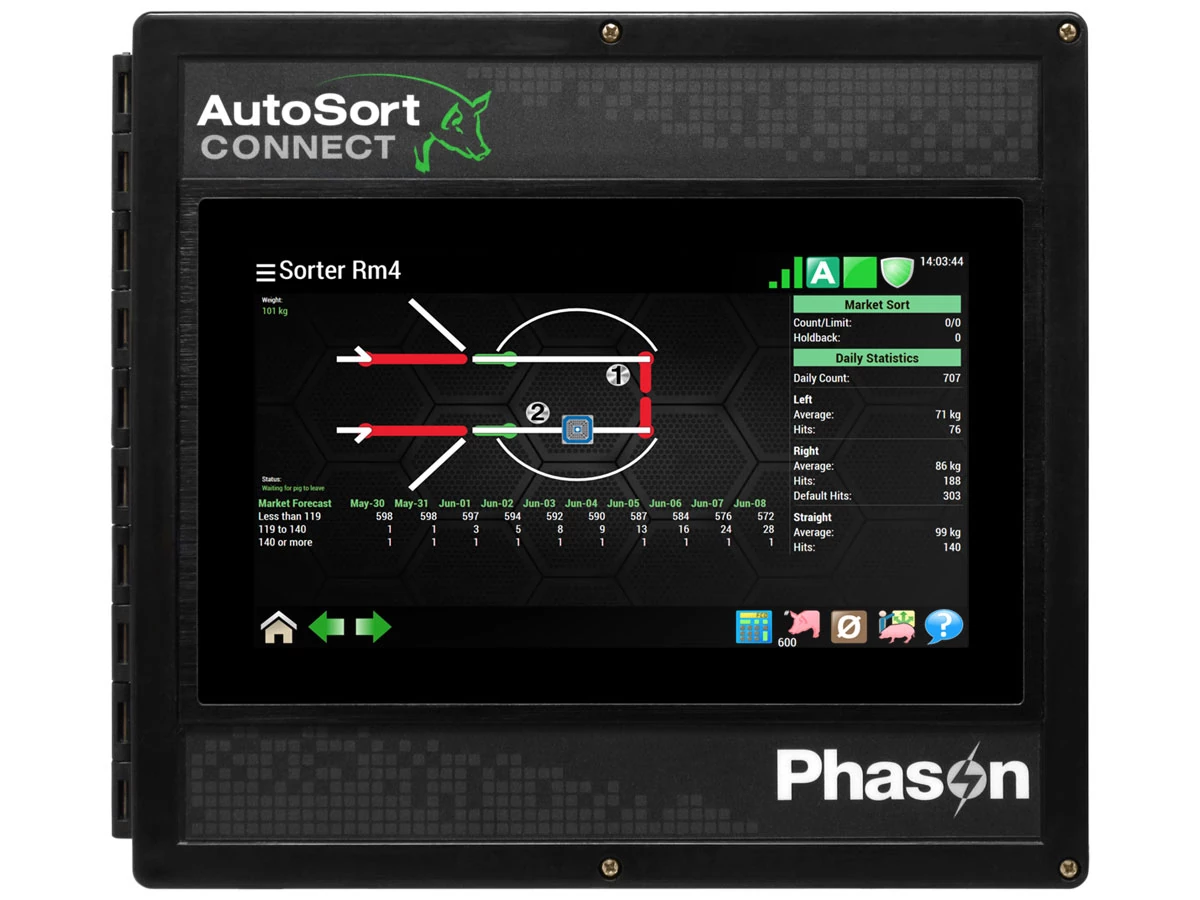

Swine

We offer comprehensive control systems designed to cater to all types of swine barns, including Gestation, Farrowing, Nursery, and Finisher barns. Our technology enables farmers to efficiently manage and adjust the environment within their barns, regardless of size or type, ensuring the well-being and comfort of their livestock.

See more

Dairy

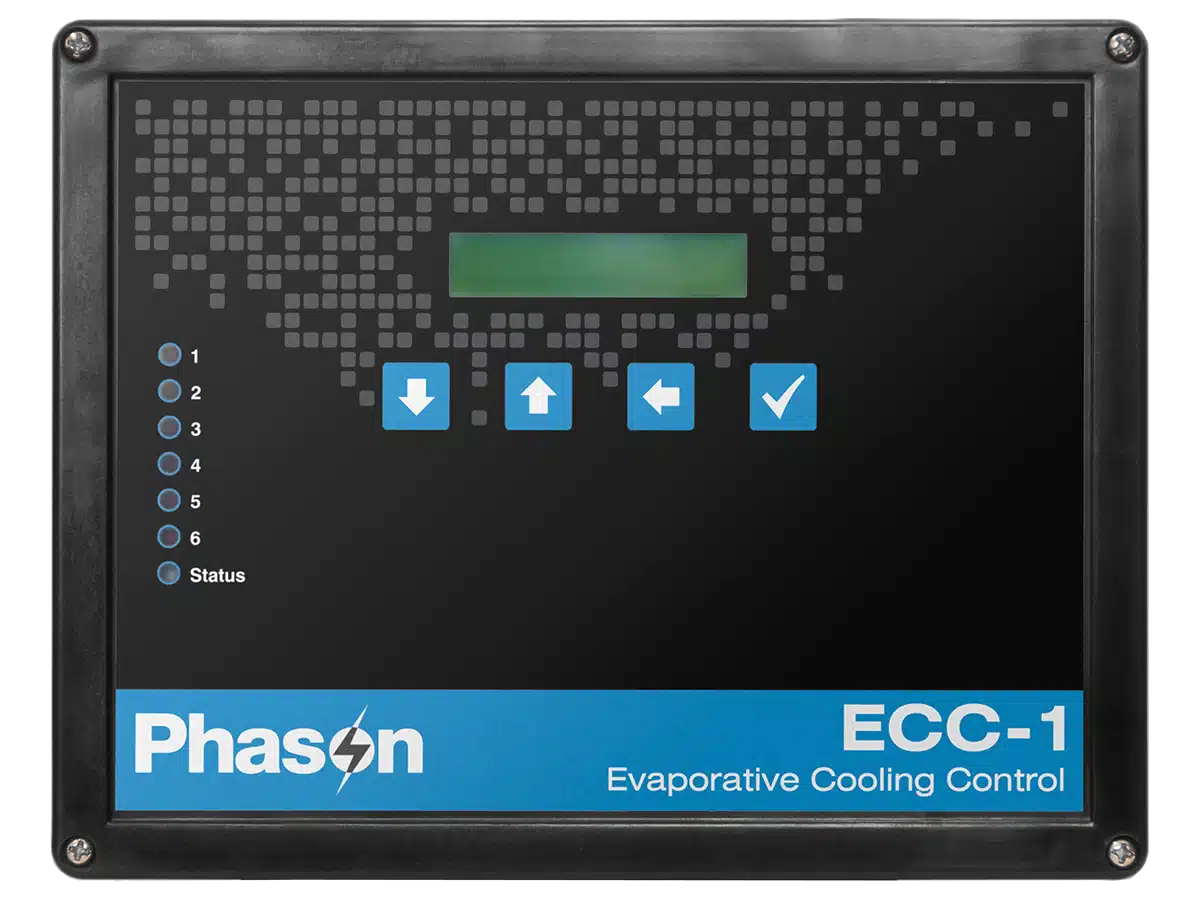

For dairy operations, our solutions are geared towards optimizing ventilation, cooling, and lighting. We cater to farms of all sizes, from small family-run operations to large-scale commercial ventures. Our systems are designed to maintain the perfect balance within dairy barns, promoting health and productivity among the livestock.

See more

Poultry

In the poultry sector, our solutions are adept at controlling ventilation, cooling, feeding, and lighting systems for both Broiler and Layer operations. We understand the critical role these factors play in the health and efficiency of poultry production, and our systems are engineered to ensure the best possible environment for growth.

See more

Greenhouse

Our greenhouse solutions are focused on creating the ideal environmental conditions for plant growth. We offer advanced control systems for ventilation, managing fans, sprinklers, lights, and more. These systems are designed to ensure that greenhouse operators can achieve and maintain the perfect climate for their products, maximizing yield and quality.

See more

Customer Support

Our team is ready to help.

Give us a call.

Not sure what you need? Need help figuring out which control is right for you? Give us a call or send us an email; we are happy to help!

Since converting my natural ventilation freestall barn to an automatic system controlled by the VESC1640, I have seen improved milk production and no freezeups during winter. The VESC1640 automatically adjusts variable frequency drive fans and inlet curtains, providing proper minimum ventilation and consistent temperature and air flow. On hot days, the VESC1640 controls high-pressure fog cooling using its duty cycle timer. Automatically-controlled ventilation has proven to be a great improvement over manually controlled ventilation, and the VESC1640 has the ability to make it happen.

Bob Donahue

Luckwaldt Farms, Woodville, Wisconsin

We have been using Phason controls in our barns for over 20 years. They offer a full line of controls from simple manual speed controls to full automation solutions. Their NEW AutoFlex Connect is truly AWESOME and designed with the farmer in mind.

Irvin Waldner

Grand Colony, Oakville, Manitoba

The biggest feature of the AutoFlex Connect for us was ease-of-use and the remote access. Also, the experience we’ve had with Phason is we’ve had very durable controllers. That’s definitely a huge feature. We’ve had controllers in farms for over 25 years that are still functioning without any issues. Phason has proven to be reliable.

Johnny Prejet, General Manager

Porcherie La du Onze, Notre Dame de Lourdes, Manitoba

On the AutoFlex... zero problems. I like the way it controls the environment. There hasn't been any glitches. The boys did a good job of wiring that thing in because it's been going trouble free. I like the simplicity, I don't think I want any other controller.

Joel Hofer

Cedar Grove Hogs, Platte, South Dakota

For pullet rearing and egg production, I use the Supra to control my variable and single-speed fans and ceiling inlets. I use the timing feature to operate the feed system and lights at chosen times. Using multiple temperature probes lets me take advantage of the average room temperature and provides a backup if a probe fails. Another helpful feature I use is the Supra saver. It acts as a backup for my settings and makes it easy to change settings on one Supra and then transfer them to another.

Hermann Grauer

Nature’s Farm, Steinbach, Manitoba

I use two Supras in my double-wide tunnel-vent swine finishing building. Each Supra controls six pit fans, six tunnel fans, the tunnel curtain, ceiling inlets, and two heaters. It also provides evaporative cooling by operating the misters on a timer at high temperatures. When the Supra switches to tunnel mode, I have the option to switch off certain fans and close the ceiling inlets to maximize the cooling effect. Controlling everything from my Supras is convenient, gives me effective ventilation, and minimizes my electrical costs.

Tom Dressel

Medford, Minnesota

Number of Phason controls worldwide:

400000 +